Discover the benefits of eva blocks and charcoal foam as we delve into their purpose and applications. Additionally, learn how Ideastep, a trusted provider, ensures top-notch after-sales service for black foam blocks. Whether you’re seeking to understand the uses of these materials or looking for reliable post-purchase support, this article has got you covered.

Can you provide an alternative phrase for “what is charcoal foam?”

Charcoal foam is a versatile material that finds application in various industries. It serves multiple purposes, making it highly sought after for a range of uses. One of its primary uses is in packing and shipping, where it provides excellent cushioning and protection for delicate items. The foam’s ability to absorb impact helps prevent damage during transportation.

Additionally, charcoal foam is widely used for acoustical dampening and soundproofing purposes. Its unique properties allow it to absorb sound waves, reducing noise and creating a quieter environment. This makes it ideal for applications in recording studios, theaters, and even residential spaces where noise reduction is desired.

Foam inserts for cases, such as those used for cameras and guns, also benefit from the qualities of charcoal foam. Its firmness and density make it an excellent choice for providing cushioning and support, ensuring the safety of sensitive equipment during transport or storage.

It is important to note that charcoal foam is available in a firmness level of extra firm only. Different foam types have varying firmness options, so it is essential to consult a foam density and ILD (Indentation Load Deflection) chart to determine the most suitable foam for specific needs.

In conclusion, charcoal foam is a versatile material with diverse applications. Its uses range from providing protection during shipping to enhancing acoustics in various settings. The availability of different firmness options for different foam types ensures that specific requirements can be met effectively.

What are the various classifications of EVA foam grades?

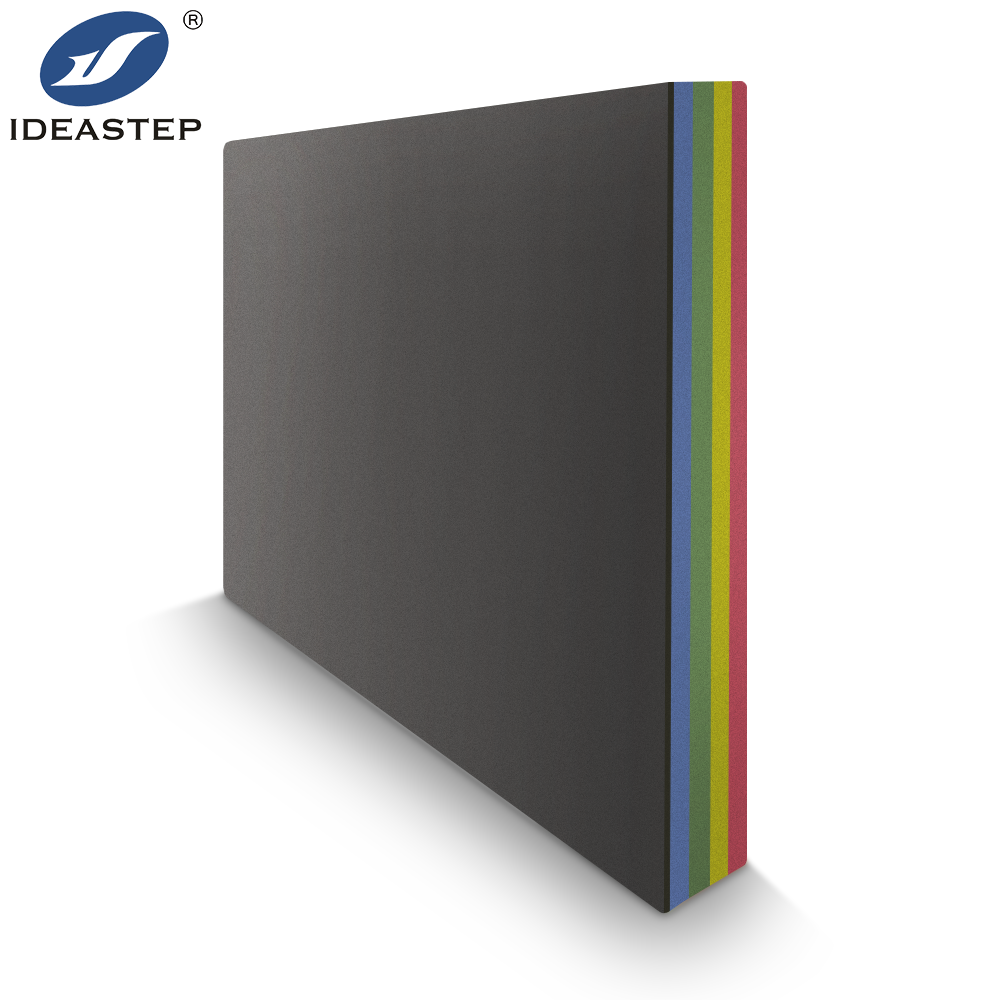

Grade c is the lowest quality of EVA foam. It has a duller color compared to grade a and b, and the surface may have more bubbles and imperfections. The elasticity of grade c is not as good as grade a and b.

EVA foam is widely used in various industries due to its versatility and excellent properties. It is commonly used in packaging, sports equipment, footwear, and even in the automotive industry. The different grades of EVA foam allow manufacturers to choose the most suitable option for their specific application.

Grade a EVA foam is often preferred for applications where aesthetics and high-quality appearance are important. Its bright color and smooth surface with minimal bubbles make it visually appealing. Additionally, grade a EVA foam offers better elasticity, making it suitable for products that require flexibility and cushioning.

Grade b EVA foam, on the other hand, is made from recycled plastic. While it may not have the same vibrant color as grade a, it still provides a smooth surface. However, it does have more bubbles compared to grade a, and its elasticity may not be as good. Despite these differences, grade b EVA foam is still a cost-effective option for many applications.

Grade c EVA foam, being the lowest quality grade, is often used in applications where appearance and elasticity are not crucial factors. Its duller color and potential imperfections make it less appealing visually. However, it can still serve its purpose in applications that require basic cushioning or padding.

In conclusion, the different grades of EVA foam, namely grade a, b, and c, define the quality and characteristics of the foam. Grade a offers a brighter color, smooth surface, and better elasticity. Grade b is made from recycled plastic, has more bubbles, and provides some elasticity. Grade c is the lowest quality option with a duller color and potentially more imperfections. Manufacturers can choose the most suitable grade of EVA foam based on their specific requirements and budget.